Through the lenses of time:

History seen through glasses

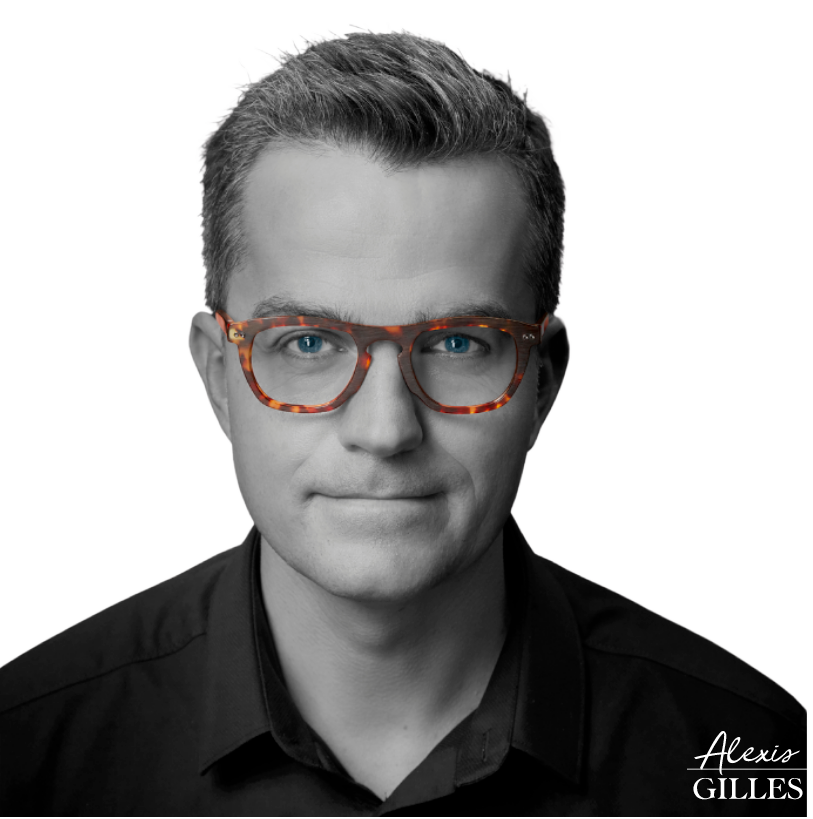

- Development of an innovation In 2019, I went for 6 weeks to complete all the necessary training at the MOF (best workers in France) school in Morez in the Jura. I then became an eyewear maker. So I had the foundations to start my R&D in order to develop my own creations.

- Soul of the brand I then had to create my own workshop, buy the right machines and my raw materials. Look up, the universe has no limits, nor does mine, so look up!

- The origin of our project I am an optician, graduated in 2001 from the LILLE Optical School where I was taught a love for this profession.

- Creation of Atavu Hours, days, months and nights, this is how I carried out my research and developed my methodology to design my frames. In 2021, it was the official launch of my first creations.

![]()

Made in France

Our workshop is located in the heights of France, the frames are created and assembled there.

![]()

Repairability

All parts of the frames are separable and therefore easily replaceable.

![]()

Eco-design

We only produce when necessary, when an order is placed. No unnecessary pollution and as little waste as possible.

Medical

My training as an optician and my passion for this profession allowed me to acquire essential experience to become an eyewear maker and create frames that meet the expectations of customers and opticians.

For wearers, our frames are designed for a perfect fit on the nose with, in addition, an accentuated contact surface to increase the weight distribution of a frame and avoid too much contact with the cheekbones.

The branches are equipped with interchangeable springs, the tip of the branch is rounded and the ear passage is thinned. The frames are inclined according to professional practices so that your vision is perfect after fitting the corrective lenses. The opening of the branches and the covering are careful for a feeling of comfort from the moment you try them on in store.

For opticians, my frames are perfectly balanced and access to adjustment points is optimized. This means that the frame can be better adjusted to each body shape after fitting the lenses.

Our know-how

I have been an optician since 2001. I have always been committed to serving my patients to meet their visual and comfort expectations. See and be seen, this is a slogan that best defines me.

When I became an eyewear maker, I was able to learn to master the manufacture of frames and bring all my experience to the development of an elegant and comfortable product.

To become an eyewear maker, I had the honor of being trained by the best French eyewear workers in the Jura. These trainers, these friends today, passed on to me the love of glasses through their teaching. We exchange regularly to continue to improve my knowledge and develop my frames ever closer to excellence.

As we do not produce on an assembly line, the design of the frames also evolves thanks to my partner opticians and their patient base, which greatly contributes to nourishing my knowledge and adjusting my designs.